Page 35 - 机械工程材料2024年第十一期

P. 35

王加康,等: Cr 2 O 3 掺杂BS-PMS-PZT大功率压电陶瓷的电学性能及温度稳定性

55 [7] EITEL R E,RANDALL C A,SHROUT T R,et al.

Applied Physics,2005,38(9):1464-1469.

50

压电常数下降率/% 45 New high temperature morphotropic phase boundary

piezoelectrics based on Bi(Me)O 3 -PbTiO 3 ceramics[J].

40

Japanese Journal of Applied Physics,2001,40(10):

35

5999.

30 [8] YIN H,WANG Y,KUANG B,et al. Phase transition

0 0.2 0.4 0.6 0.8 1.0 and thermal stability of 5.4BiScO 3 - (94.6-x)PbZrO 3 -

Cr 2 O 3 原子分数/%

xPbTiO 3 ternary system with excellent piezoelectric

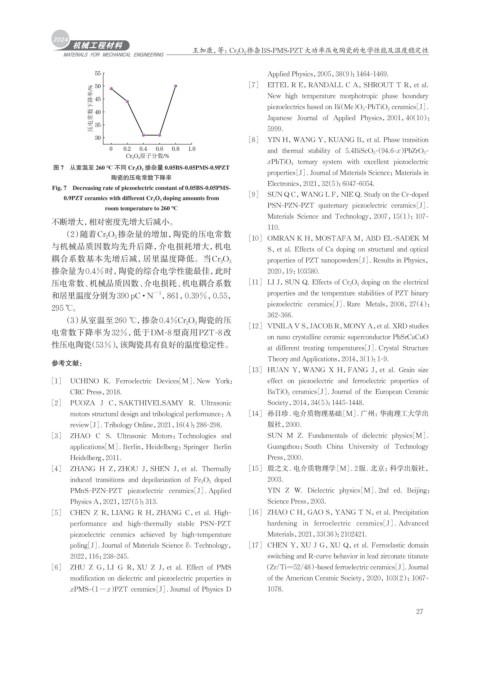

图 7 从室温至 260 ℃ 不同 Cr 2 O 3 掺杂量 0.05BS-0.05PMS-0.9PZT

properties[J]. Journal of Materials Science:Materials in

陶瓷的压电常数下降率

Fig. 7 Decreasing rate of piezoelectric constant of 0.05BS-0.05PMS- Electronics,2021,32(5):6047-6054.

0.9PZT ceramics with different Cr 2 O 3 doping amounts from [9] SUN Q C,WANG L F,NIE Q. Study on the Cr-doped

room temperature to 260 ℃ PSN-PZN-PZT quaternary piezoelectric ceramics[J].

Materials Science and Technology,2007,15(1):107-

不断增大,相对密度先增大后减小。

110.

(2)随着Cr 2 O 3 掺杂量的增加,陶瓷的压电常数

[10] OMRAN K H,MOSTAFA M,ABD EL-SADEK M

与机械品质因数均先升后降,介电损耗增大,机电 S,et al. Effects of Ca doping on structural and optical

properties of PZT nanopowders[J]. Results in Physics,

耦合系数基本先增后减,居里温度降低。当Cr 2 O 3

掺杂量为0.4%时,陶瓷的综合电学性能最佳,此时 2020,19:103580.

压电常数、机械品质因数、介电损耗、机电耦合系数 [11] LI J,SUN Q. Effects of Cr 2 O 3 doping on the electrical

和居里温度分别为390 pC · N −1 ,861,0.39%,0.55, properties and the temperature stabilities of PZT binary

piezoelectric ceramics[J]. Rare Metals,2008,27(4):

295 ℃。

362-366.

(3) 从室温至260 ℃,掺杂0.4%Cr 2 O 3 陶瓷的压

[12] VINILA V S,JACOB R,MONY A,et al. XRD studies

电常数下降率为32%,低于DM-8型商用PZT-8改

on nano crystalline ceramic superconductor PbSrCaCuO

性压电陶瓷(53%) ,该陶瓷具有良好的温度稳定性。 at different treating temperatures[J]. Crystal Structure

Theory and Applications,2014,3(1):1-9.

参考文献:

[13] HUAN Y,WANG X H,FANG J,et al. Grain size

[1] UCHINO K. Ferroelectric Devices[M]. New York: effect on piezoelectric and ferroelectric properties of

CRC Press,2018. BaTiO 3 ceramics[J]. Journal of the European Ceramic

[2] PUOZA J C,SAKTHIVELSAMY R. Ultrasonic Society,2014,34(5):1445-1448.

motors structural design and tribological performance:A [14] 孙目珍. 电介质物理基础 [M]. 广州:华南理工大学出

review[J]. Tribology Online,2021,16(4):286-298. 版社,2000.

[3] ZHAO C S. Ultrasonic Motors:Technologies and SUN M Z. Fundamentals of dielectric physics[M].

applications[M]. Berlin,Heidelberg:Springer Berlin Guangzhou:South China University of Technology

Heidelberg,2011. Press,2000.

[4] ZHANG H Z,ZHOU J,SHEN J,et al. Thermally [15] 殷之文. 电介质物理学 [M]. 2版. 北京:科学出版社,

induced transitions and depolarization of Fe 2 O 3 doped 2003.

PMnS-PZN-PZT piezoelectric ceramics[J]. Applied YIN Z W. Dielectric physics[M]. 2nd ed. Beijing:

Physics A,2021,127(5):313. Science Press,2003.

[5] CHEN Z R,LIANG R H,ZHANG C,et al. High- [16] ZHAO C H,GAO S,YANG T N,et al. Precipitation

performance and high-thermally stable PSN-PZT hardening in ferroelectric ceramics[J]. Advanced

piezoelectric ceramics achieved by high-temperature Materials,2021,33(36):2102421.

poling[J]. Journal of Materials Science & Technology, [17] CHEN Y,XU J G,XU Q,et al. Ferroelastic domain

2022,116:238-245. switching and R-curve behavior in lead zirconate titanate

[6] ZHU Z G,LI G R,XU Z J,et al. Effect of PMS (Zr/Ti=52/48) -based ferroelectric ceramics[J]. Journal

modification on dielectric and piezoelectric properties in of the American Ceramic Society,2020,103(2):1067-

xPMS- (1−x)PZT ceramics[J]. Journal of Physics D 1078.

27