Page 140 - 机械工程材料2024年第十一期

P. 140

汲高飞,等:基于响应面法和BP神经网络的7050铝合金腐蚀疲劳寿命预测及对比

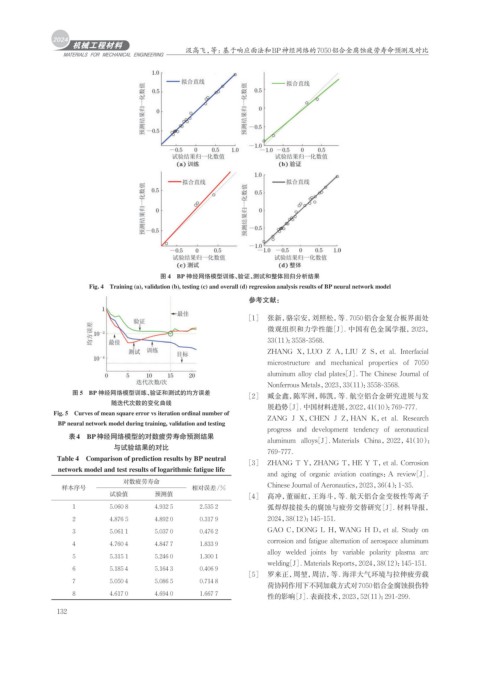

图 4 BP 神经网络模型训练、验证、测试和整体回归分析结果

Fig. 4 Training (a), validation (b), testing (c) and overall (d) regression analysis results of BP neural network model

参考文献:

[1] 张新,骆宗安,刘照松,等. 7050铝合金复合板界面处

微观组织和力学性能[J]. 中国有色金属学报,2023,

33(11):3558-3568.

ZHANG X,LUO Z A,LIU Z S,et al. Interfacial

microstructure and mechanical properties of 7050

aluminum alloy clad plates[J]. The Chinese Journal of

Nonferrous Metals,2023,33(11):3558-3568.

图 5 BP 神经网络模型训练、验证和测试的均方误差

[2] 臧金鑫,陈军洲,韩凯,等. 航空铝合金研究进展与发

随迭代次数的变化曲线

Fig. 5 Curves of mean square error vs iteration ordinal number of 展趋势[J]. 中国材料进展,2022,41(10):769-777.

BP neural network model during training, validation and testing ZANG J X,CHEN J Z,HAN K,et al. Research

progress and development tendency of aeronautical

表4 BP神经网络模型的对数疲劳寿命预测结果

aluminum alloys[J]. Materials China,2022,41(10):

与试验结果的对比

Table 4 Comparison of prediction results by BP neutral 769-777.

network model and test results of logarithmic fatigue life [3] ZHANG T Y,ZHANG T,HE Y T,et al. Corrosion

and aging of organic aviation coatings:A review[J].

对数疲劳寿命

样本序号 相对误差/% Chinese Journal of Aeronautics,2023,36(4):1-35.

试验值 预测值 [4] 高冲,董丽虹,王海斗,等. 航天铝合金变极性等离子

1 5.060 8 4.932 5 2.535 2 弧焊焊接接头的腐蚀与疲劳交替研究[J]. 材料导报,

2 4.876 5 4.892 0 0.317 9 2024,38(12):145-151.

3 5.061 1 5.037 0 0.476 2 GAO C,DONG L H,WANG H D,et al. Study on

corrosion and fatigue alternation of aerospace aluminum

4 4.760 4 4.847 7 1.833 9

alloy welded joints by variable polarity plasma arc

5 5.315 1 5.246 0 1.300 1

welding[J]. Materials Reports,2024,38(12):145-151.

6 5.185 4 5.164 3 0.406 9

[5] 罗来正,周堃,周洁,等. 海洋大气环境与拉伸疲劳载

7 5.050 4 5.086 5 0.714 8

荷协同作用下不同加载方式对7050铝合金腐蚀损伤特

8 4.617 0 4.694 0 1.667 7

性的影响[J]. 表面技术,2023,52(11):291-299.

132