Page 67 - 机械工程材料2024年第十一期

P. 67

崔 璐,等: QT1100连续油管钢的抗液固两相流冲蚀性能

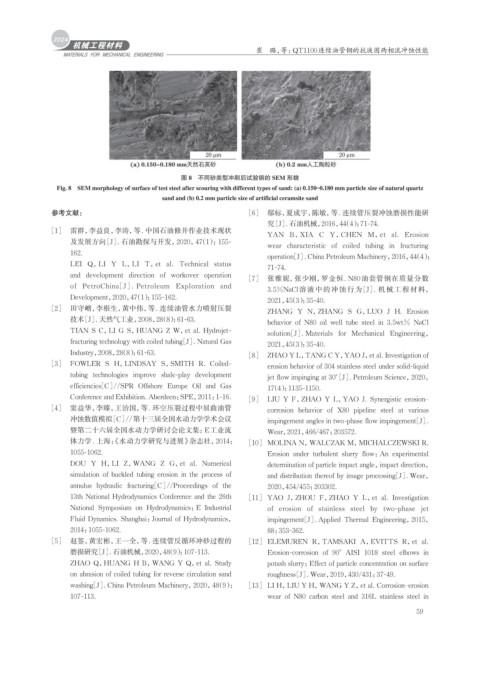

图 8 不同砂类型冲刷后试验钢的 SEM 形貌

Fig. 8 SEM morphology of surface of test steel after scouring with different types of sand: (a) 0.150–0.180 mm particle size of natural quartz

sand and (b) 0.2 mm particle size of artificial ceramsite sand

参考文献: [6] 鄢标,夏成宇,陈敏,等. 连续管压裂冲蚀磨损性能研

究[J]. 石油机械,2016,44(4):71-74.

[1] 雷群,李益良,李涛,等. 中国石油修井作业技术现状

YAN B,XIA C Y,CHEN M,et al. Erosion

及发展方向[J]. 石油勘探与开发,2020,47(1):155-

wear characteristic of coiled tubing in fracturing

162.

operation[J]. China Petroleum Machinery,2016,44(4):

LEI Q,LI Y L,LI T,et al. Technical status

71-74.

and development direction of workover operation

[7] 张雅妮,张少刚,罗金恒. N80 油套管钢在质量分数

of PetroChina[J]. Petroleum Exploration and

3.5%NaCl溶液中的冲蚀行为 [J]. 机械工程材料,

Development,2020,47(1):155-162.

2021,45(3):35-40.

[2] 田守嶒,李根生,黄中伟,等. 连续油管水力喷射压裂

ZHANG Y N,ZHANG S G,LUO J H. Erosion

技术[J]. 天然气工业,2008,28(8):61-63.

behavior of N80 oil well tube steel in 3.5wt% NaCl

TIAN S C,LI G S,HUANG Z W,et al. Hydrojet- solution[J]. Materials for Mechanical Engineering,

fracturing technology with coiled tubing[J]. Natural Gas 2021,45(3):35-40.

Industry,2008,28(8):61-63. [8] ZHAO Y L,TANG C Y,YAO J,et al. Investigation of

[3] FOWLER S H,LINDSAY S,SMITH R. Coiled- erosion behavior of 304 stainless steel under solid-liquid

tubing technologies improve shale-play development jet flow impinging at 30° [J]. Petroleum Science,2020,

efficiencies[C]//SPR Offshore Europe Oil and Gas 17(4):1135-1150.

Conference and Exhibition. Aberdeen:SPE,2011:1-16. [9] LIU Y F,ZHAO Y L,YAO J. Synergistic erosion‒

[4] 窦益华,李臻,王治国,等. 环空压裂过程中屈曲油管 corrosion behavior of X80 pipeline steel at various

冲蚀数值模拟[C]//第十三届全国水动力学学术会议 impingement angles in two-phase flow impingement[J].

暨第二十六届全国水动力学研讨会论文集:E工业流 Wear,2021,466/467:203572.

体力学. 上海:《水动力学研究与进展》杂志社,2014: [10] MOLINA N,WALCZAK M,MICHALCZEWSKI R.

1055-1062. Erosion under turbulent slurry flow:An experimental

DOU Y H,LI Z,WANG Z G,et al. Numerical determination of particle impact angle,mpact direction,

i

simulation of buckled tubing erosion in the process of and distribution thereof by image processing[J]. Wear,

annulus hydraulic fracturing[C]//Proceedings of the 2020,454/455:203302.

13th National Hydrodynamics Conference and the 26th [11] YAO J,ZHOU F,ZHAO Y L,et al. Investigation

National Symposium on Hydrodynamics:E Industrial of erosion of stainless steel by two-phase jet

Fluid Dynamics. Shanghai:Journal of Hydrodynamics, impingement[J]. Applied Thermal Engineering,2015,

2014:1055-1062. 88:353-362.

[5] 赵签,黄宏彬,王一全,等. 连续管反循环冲砂过程的 [12] ELEMUREN R,TAMSAKI A,EVITTS R,et al.

磨损研究[J]. 石油机械,2020,48(9):107-113. Erosion-corrosion of 90° AISI 1018 steel elbows in

ZHAO Q,HUANG H B,WANG Y Q,et al. Study potash slurry:Effect of particle concentration on surface

on abrasion of coiled tubing for reverse circulation sand roughness[J]. Wear,2019,430/431:37-49.

washing[J]. China Petroleum Machinery,2020,48(9): [13] LI H,LIU Y H,WANG Y Z,et al. Corrosion‒erosion

107-113. wear of N80 carbon steel and 316L stainless steel in

59