Page 74 - 机械工程材料2024年第十一期

P. 74

蔡 军,等:工艺参数对热丝脉冲TIG堆焊Inconel 625合金成形性能及组织的影响

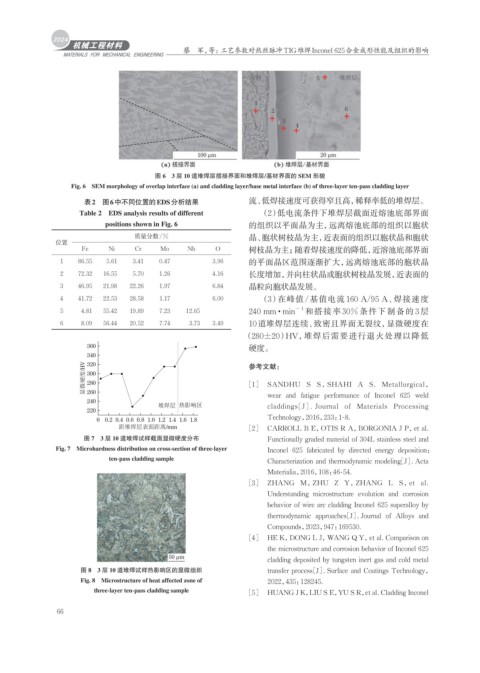

图 6 3 层 10 道堆焊层搭接界面和堆焊层/基材界面的 SEM 形貌

Fig. 6 SEM morphology of overlap interface (a) and cladding layer/base metal interface (b) of three-layer ten-pass cladding layer

表2 图6中不同位置的EDS分析结果 流、低焊接速度可获得窄且高,稀释率低的堆焊层。

Table 2 EDS analysis results of different (2) 低电流条件下堆焊层截面近熔池底部界面

positions shown in Fig. 6 的组织以平面晶为主,远离熔池底部的组织以胞状

质量分数/% 晶、胞状树枝晶为主,近表面的组织以胞状晶和胞状

位置

Fe Ni Cr Mo Nb O 树枝晶为主;随着焊接速度的降低,近溶池底部界面

1 86.55 5.61 3.41 0.47 3.96 的平面晶区范围逐渐扩大,远离熔池底部的胞状晶

2 72.32 16.55 5.70 1.26 4.16 长度增加,并向柱状晶或胞状树枝晶发展,近表面的

3 46.95 21.98 22.26 1.97 6.84 晶粒向胞状晶发展。

4 41.72 22.53 28.58 1.17 6.00 (3)在峰值/基值电流 160 A/95 A、焊接速度

5 4.81 55.42 19.89 7.23 12.65 240 mm · min − 1 和搭接率 30%条件下制备的 3 层

6 8.09 56.44 20.52 7.74 3.73 3.49 10道堆焊层连续、致密且界面无裂纹,显微硬度在

(280±20)

HV,堆焊后需要进行退火处理以降低

360 硬度。

340 参考文献:

320

显微硬度/HV 300 [1] SANDHU S S,SHAHI A S. Metallurgical,

280

260

wear and fatigue performance of Inconel 625 weld

240

堆焊层 热影响区 claddings[J]. Journal of Materials Processing

220

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 Technology,2016,233:1-8.

距堆焊层表面距离/mm [2] CARROLL B E,OTIS R A,BORGONIA J P,et al.

图 7 3 层 10 道堆焊试样截面显微硬度分布 Functionally graded material of 304L stainless steel and

Fig. 7 Microhardness distribution on cross-section of three-layer Inconel 625 fabricated by directed energy deposition:

ten-pass cladding sample

Characterization and thermodynamic modeling[J]. Acta

Materialia,2016,108:46-54.

[3] ZHANG M,ZHU Z Y,ZHANG L S,et al.

Understanding microstructure evolution and corrosion

behavior of wire arc cladding Inconel 625 superalloy by

thermodynamic approaches[J]. Journal of Alloys and

Compounds,2023,947:169530.

[4] HE K,DONG L J,WANG Q Y,et al. Comparison on

the microstructure and corrosion behavior of Inconel 625

cladding deposited by tungsten inert gas and cold metal

图 8 3 层 10 道堆焊试样热影响区的显微组织 transfer process[J]. Surface and Coatings Technology,

Fig. 8 Microstructure of heat affected zone of 2022,435:128245.

three-layer ten-pass cladding sample [5] HUANG J K,LIU S E,YU S R,et al. Cladding Inconel

66